From space missions to smart factories

By Joseph Kong, Head of Digital Industries, Siemens Thailand

Personal computers, GPS, mobile phones, digital cameras, the internet: many of the technologies in our lives today are older than we might think. They originate from concepts from the 1960s and 70s – an enormously creative, innovative period.

Another innovation on everyone’s mind is the digital twin which many scientists and engineers today describe as the backbone of a new industrial revolution. A digital twin is a virtual representation of a physical object. This digital counterpart enables real-time monitoring, diagnostics and predictive maintenance, which significantly increases operational efficiency.

Physical models of NASA spacecrafts – the precursors of digital twin

The initial idea of this technology has its origins in NASA – National Aeronautics and Space Administration space missions around 60 years ago. Space missions were expensive and risky, so people preferred to simulate on safe ground what they would have to be prepared for in space.

A simple idea was born, and this is still the key benefit of digital twin today. The term itself was only popularized late, in 2010 to be precise, by NASA´s Michael Grieves and John Vickers. Thereby marking its transition from a tool used in space exploration to an industrial revolution.

The rise of the digital twin and the IoT

If the digital twin is the backbone of the industry of the future, then data is the life blood of the digital twin. The more data, the more precise the digital representation and the more opportunities arise. IoT (Internet of Things) devices, which are being deployed everywhere in our world in exploding numbers, provide precisely this data, which is used intelligently for digital twin.

According to Statista, there are already 15.9 billion IoT devices in use worldwide, and this figure is expected to more than double by 2033. Many of these are already being used in industrial plants and production facilities enabling engineers to simulate every aspect in the virtual environment, from the products themselves to the machines and entire production lines.

Siemens drives the development forward since the early days

Siemens has played a significant role in space exploration through its software and digital solutions which have since found transformative applications in manufacturing.

In the 1970s, Siemens was already focusing on data processing technologies and since then its early technological advancements such as automation and control systems and digitalization laid the foundation for the technologies that power the IoT today. Digital twin technology was originally designed to simulate and monitor complex systems in space. By creating a digital replica of physical assets, engineers could predict how spacecraft components would respond to the extreme conditions of space.

Today, Siemens applies digital twin in manufacturing to optimize production lines, anticipate maintenance needs, and reduce downtime. By enabling virtual testing and refinement of systems, manufacturers can improve efficiency, reduce waste, and achieve high precision without risking costly real-world trial-and-error.

In 2012, Siemens collaborated with NASA on the Mars mission “Curiosity.” The company provided the software solutions that were used to develop, simulate, and test the Mars rover. In 2015, Siemens introduced the concept of digital twin for industrial use at Hannover Fair in Germany and presented the technology for different branches of industry, including the process industries and machine building.

The foundation of Industry 4.0 and the future of smart, sustainable factories

Digital twin is now at the heart of the much talked about Industry 4.0 – the culmination of the digitalization of industrial processes. Digital twin is not only relevant during ongoing operations, but also from the very first minute an idea or business model is created.

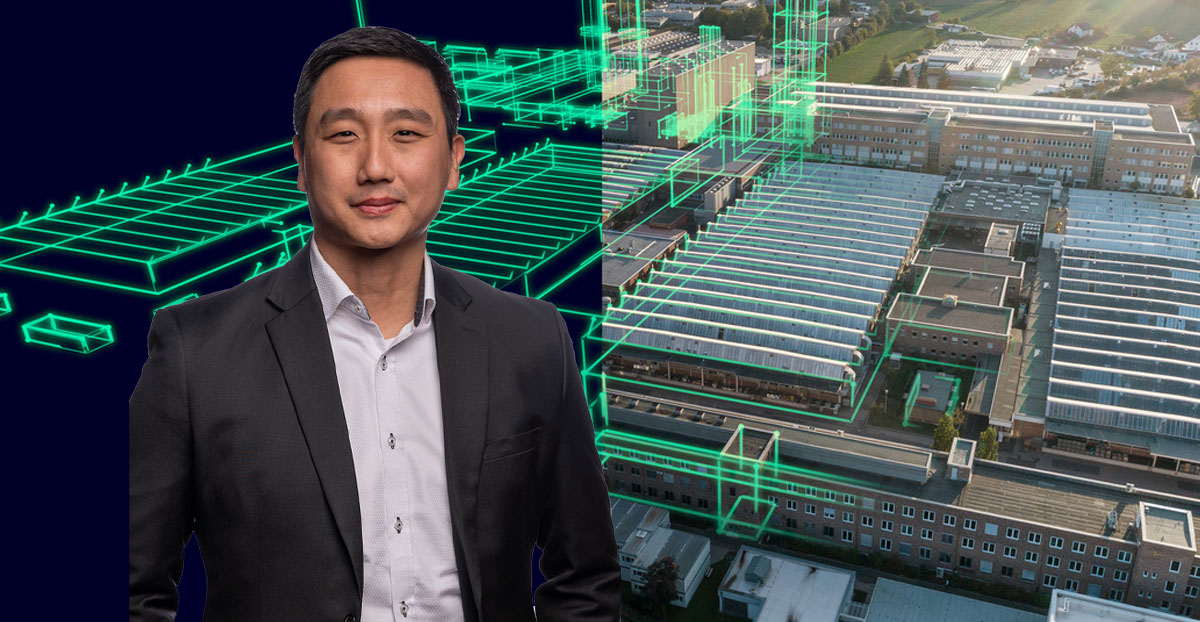

Today, a smart factory is first created as a digital twin and only much later in the real world. Precise simulations not only make it possible to avoid roadblocks and foresee dangers, but also to design all processes as efficiently as possible so that the factory of the future is not only productive, but above all highly sustainable.

And yet this is just the beginning: the combination of digital twin and AI will enable computers to independently design optimized products and processes and proactively support decision-makers in industries in their innovations and planning, operations and maintenance.

Combining the real and the digital worlds

The digital twin is a prime example of what it means to connect the real with the digital worlds to create a sustainable impact. By creating digital replicas of physical assets, businesses gain insights that allow them to optimize processes, predict challenges, and innovate responsibly.

For all, it is important to understand that physical reality and the human being at its center will always be the point of reference. Digitalization, like AI, is never a purpose, but no more but also no less than a powerful enabler to transform the everyday for the better.

Experience firsthand Siemens’ pioneering software solutions for aerospace industry at Thailand Space Week 2024 during 7-9 November 2024 at IMPACT Muang Thong Thani.

Organized by the Geo-Informatics and Space Technology Development Agency (GISTDA) under the theme “Converging Technologies, Connecting People”, Siemens will showcase technology from the open digital business platform #SiemensXcelerator, including a comprehensive suite of software products supporting all areas of aerospace development, from System Design, Simulation & Testing, and Product Lifecycle Management (PLM) to Manufacturing Process Management, under the Model-Based Systems Engineering (MBSE) and Digital Threads concepts. These solutions play a vital role in linking every step from design to production in satellite systems and space technology development.